- IoT for real-time monitoring

- IoT for data processing

- IoT saves a company money

- IoT improves the environment

- IoT automates work

- IoT and insurance

- Why not all companies are implementing IoT

- Conclusion

Fleet owners know that maintaining optimal vehicle performance indicators, such as tire pressure, prolongs the life of vehicles and saves them thousands of dollars. In this article, we'll tell you how IoT sensors for fleet management are improving the way companies operate and share some tips on how to implement this technology.

IoT for real-time monitoring

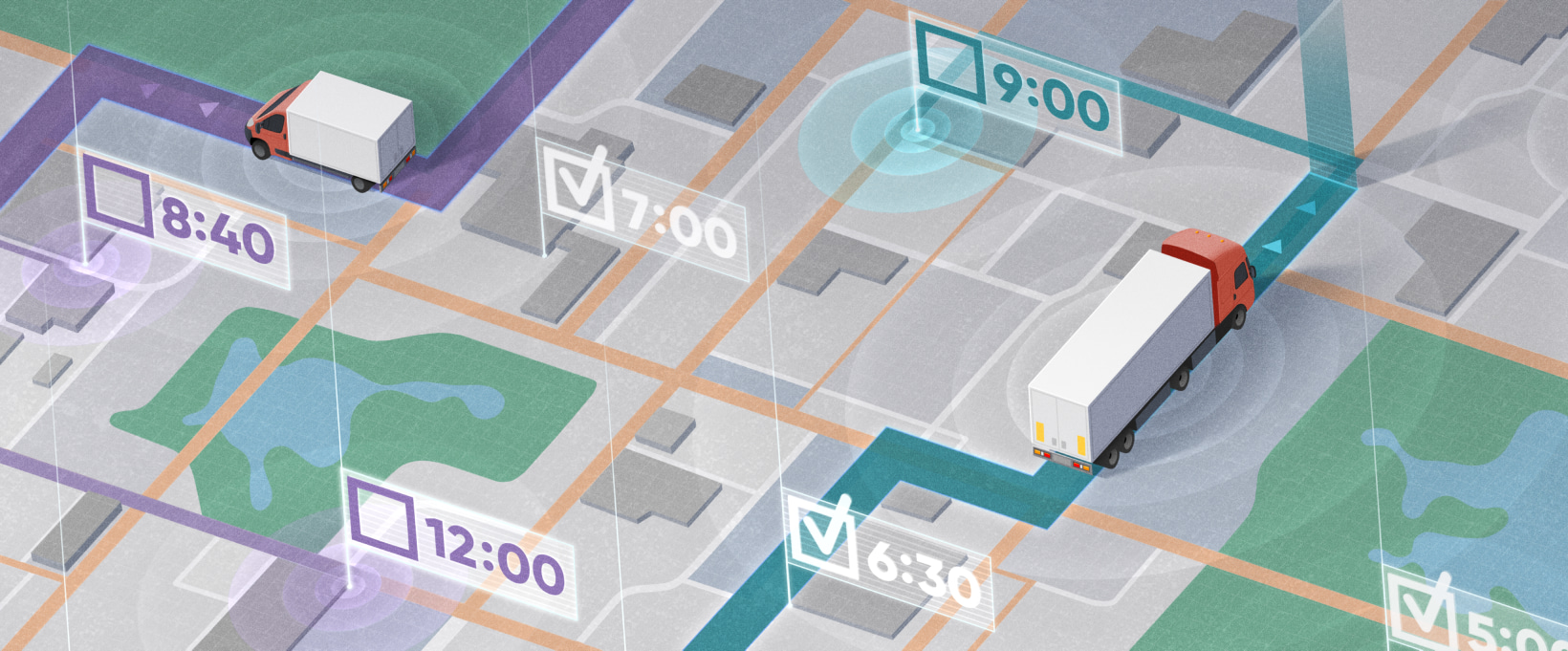

IoT devices allow for the real-time monitoring of vehicles via fleet management GPS tracking software and video streaming.

GPS enables managers to monitor the behavior of drivers on the road and analyze how fast they are moving, whether they obey traffic rules, and whether they make needless stops. This measure motivates drivers, eliminates potential risks, and enhances safety.

When using video streaming, the fleet manager connects to the dashboard camera installed in a car via API. By doing so, the manager can see where the car is going through the eyes of the driver. Such a telematics camera gives an idea of the driving behavior and the state of the vehicle. It can become rock hard evidence in case of a car accident, as all recordings are sent to the camera's video storage.

The time that used to be spent on tracking the location of vehicles and communicating it to clients can now be devoted to processing new orders, issuing invoices, improving logistics, and working on other priority tasks.

Applying fleet truck tracking GPS solutions and video streaming, operators inform clients about the exact time of vehicles’ arrivals and instantly update routes. If an accident occurs, the machine that is connected to the engine will send an alert to the office asking for help.

Any company - whether it is a logistics, courier, or taxi service - needs to deliver goods and passengers on time. Deviation from a schedule can negatively affect the company's reputation. If fleet managers learn about such delays in real-time with the help of a telematics device, they will warn clients and, if necessary, suggest a solution to the problem.

IoT for data processing

A car telematics device collects such vehicle data as speed, idle time, acceleration or braking, fuel consumption, breakdowns, tire pressure, and more. This helps vehicle fleet owners plan maintenance and avoid downtime and out-of-schedule repair costs. The good condition of vehicles, in turn, increases the loyalty of clients and even the fleet employees.

Every day, vehicle fleet managers handle large volumes of data: calculate fuel consumption, track speed, record which cars were used, and so on. In some companies, this is done manually, which is not always efficient.

IoT technology is fundamentally changing the work of fleets. Data is collected in real-time, so if a problem arises, managers promptly analyze the information and make a decision. In this way, companies improve their processes and increase their efficiency.

IoT saves a company money

Connected IoT devices measure important vehicle metrics and help fleet owners understand how productively their budgets are being spent.

For example, GPS devices provide operators with information about drivers’ speed and how hard they accelerate, and these indicators affect fuel consumption.

Austrian courier company J.R. Company GmbH has improved its logistics and driver behavior on the road with the help of the Fleet Tracker solution. More than a hundred fleet vehicles delivered nearly six thousand parcels daily. The business owner wondered how to consume less fuel, speed up delivery, and reduce the number of breakdowns. Having introduced an IoT system into its workflows, J.R. Company GmbH managed to reduce repair and replacement costs by 30% and 50% respectively and saved €90,000 per year. Such great changes have taken place thanks to tracking just one metric - driving behavior.

IoT improves the environment

Experts have calculated that, when idling, one car emits 30 million tons of carbon dioxide annually. Vehicle fleet managers can reduce this rate by analyzing the driving behavior of their employees with the help of a telematics device.

Driving style (idle speed, acceleration or braking, average speed) affects fuel-saving. By using data from IoT devices, vehicle fleet managers can enforce rules for speed, braking, idling, etc. to reduce fuel consumption and carbon dioxide emissions.

The United States Department of Energy estimates that fast acceleration and hard braking increase fuel consumption by 5-33%, depending on the type of road. By using connected devices, a company can receive auto alerts about drivers violating rules and govern its employees.

IoT automates work

IoT automates fleet processes. The time that specialists used to spend on labor-intensive tasks (doing paperwork, checking phones, or switching between programs) can now be utilized to serve more clients.

For example, route optimization software suggests drivers change directions if there is bad weather or traffic jams, and in case of accidents, it sends a message to the fleet office asking for help. This kind of innovation is changing the work of vehicle fleets for the better.

IoT and insurance

Insurance companies are encouraging the use of fleet telematics devices - with safe driving, a car is at less risk, and insurers don’t have to pay huge sums. With a monitoring program, drivers are more careful, hence fleets pay fewer fines and may claim lower insurance premiums under loyalty programs.

Why not all companies are implementing IoT

Despite the fact that applying IoT technology is profitable, only 64% of fleets use GPS sensors and automobile fleet management software. Why is not every company ready to implement this technology into its processes?

Drivers are not comfortable with interference in their work. Many of them don't like it when their work is monitored and corrected. In this case, it is necessary to explain to your employees why the data is collected, how it will affect the well-being of the fleet, and what benefits it will bring to the drivers.

The manager sees no benefit in IoT. Executives may have no idea about how the company will benefit if drivers don’t exceed 120 km/h or if tire pressure is measured. But in actual practice, IoT improves fleet management and saves you from unplanned expenses.

IoT devices are costly. Equipping all the company's vehicles with IoT sensors and ordering the development of logistics fleet management software is expensive, but this solution will pay off in the future. Expenses on calls, repairs, and fuel will reduce. Make the necessary calculations to see whether your company needs IoT devices.

Conclusion

IoT is becoming one of the best practices for vehicle fleet management. Companies that are not implementing IoT devices are missing the chance to cut the costs for operating their fleets, increase their profits and employee productivity, and gain loyal clients.

If you are aspiring to the digital transformation of your logistic business, reach out to Andersen for a consultation. We develop custom fleet management software solutions that improve companies’ logistics and supply chains and open up new opportunities for them.